Anti-skid pad TPE soft rubber soft and comfortable anti-skid pad

Contact 138 2720 9711

Product details

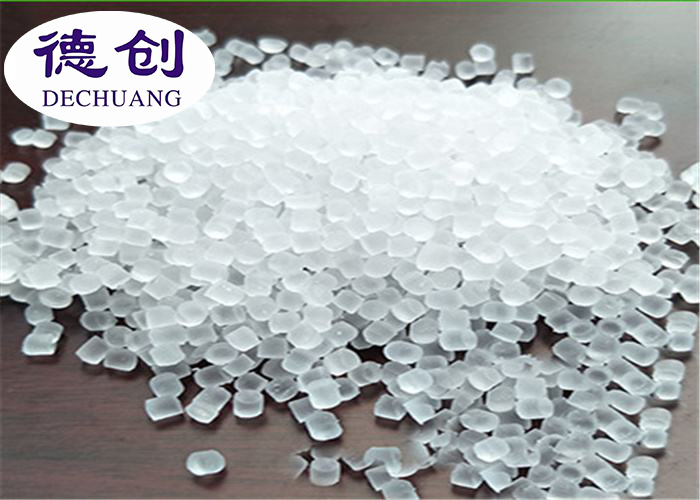

The hardness of 0 degree TPE material is tested by Shore C. The greater the data, the softer the hardness of the material. We will also use 0 to represent, one 0 represents 0 degrees, up to 8 0 ultra-soft TPE materials. The 0 degree material is usually transparent or semitransparent particles, nontoxic and odorless. Has excellent elongation up to 1500%.

The handle of 0 degree TPE material is close to that of silica gel. Generally, injection molding or pouring are used to produce sex toys, toys, gel cushions and automobile anti-skid cushions. Dechuang Chemical is a well-known domestic supplier of sex toys.

High transparency TPE8 degrees, 10 degrees, 12 degrees, 0 degrees. Emulated skin, tasteless and oily. High transparency can reach 98%. It can also produce skin color, high extensibility and excellent resilience, high tensile property, good fluidity and yellowing resistance. It can replace silica gel /PVC material without odor, oil and spray. Non-toxic and environment-friendly meet the environmental testing standards of ROHS,REACH,PAHS,EN71, etc.

The injection efficiency of 0 degree TPE is relatively low, because the hardness is too low, and the processed products shrink greatly, with shrinkage rate of 1.6~2.0%. Water lines will appear on the surface. It is recommended that the injection temperature be 120-150 degrees Celsius. The particles of 0 degree materials are all sticky, and feeding difficulties will occur in the production process. We suggest that injection molding manufacturers reduce the temperature in the blanking port area and adopt press-type auxiliary feeding, such as pressing down with a stick, which is directly effective. It is also possible to install a forced feeder with high rotating speed and low feeding mode. The heating section of the blanking area is closed.